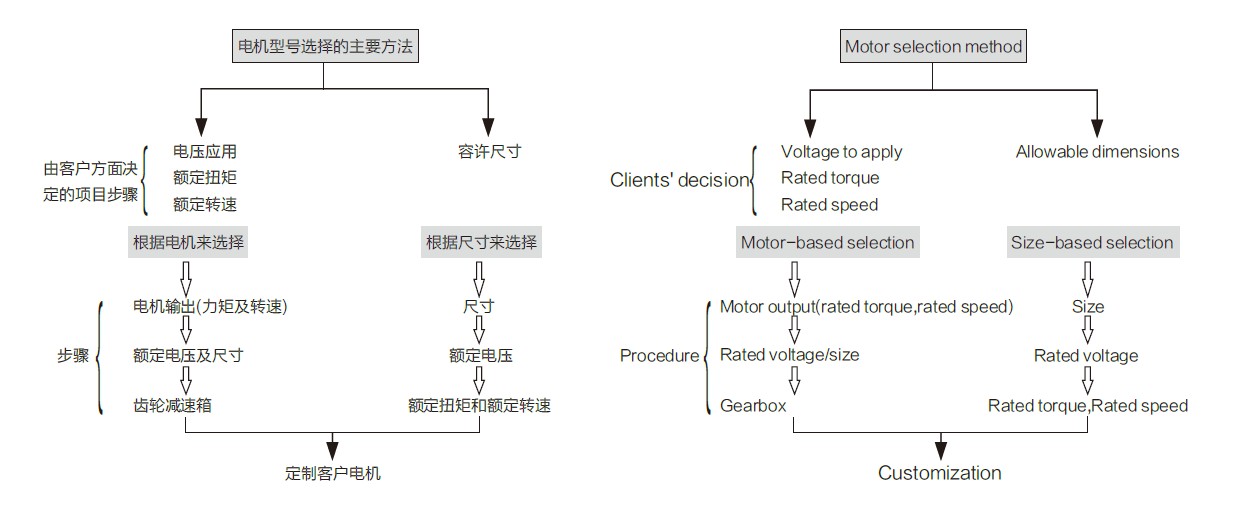

电机的选择方法

介绍电机与齿轮箱产品组合技术信息②,帮助您了解电机的选择方法

最佳选择需要考虑到电源、控制、运转条件等因素来选择无芯、铁芯或是无刷的电机。如果希望由敝公司代为选择的话,请确认好下述各项条件。

- 电源的条件:使用电压范围、整流电源或者电池、电流限制有无。

- PWM、电压变动等控制的有无

- 是否需要编码器

- 运转条件(连续、间歇、正逆、驱动时间、加锁、短路制动

- 环境状态(温度、湿度等)

- 包括齿轮箱、编码器在内的尺寸限制

下面,我们来说明一下从客户要求的基本参数来选择电机和齿轮电机的程序

供应电压 U=12 V

额定转数 NT=100 rpm,

额定扭矩 TN=5000 g.cm

齿轮箱减速 100:1,

直齿轮5级传动效率为62.4%

齿轮减速电机额定输出功率= NT × TN×/95500=100×5000/95500=5.23W

电机额定输出功率=齿轮减速电机额定输出功率/齿轮箱传动效率=5.23/0.624=8.38W